The Ultimate Guide To Using A Speed Square For Precision And Efficiency

When it comes to tools that are both versatile and indispensable in woodworking, carpentry, and DIY projects, the speed square stands out as a true game-changer. Whether you're a seasoned professional or an enthusiastic beginner, this triangular tool can simplify your tasks, improve accuracy, and save you time. Its unique design and multiple uses make it a must-have in every tool kit.

From marking perfect angles to measuring lengths and even acting as a makeshift saw guide, the speed square is more than just another tool—it's a multi-functional powerhouse. Despite its seemingly simple appearance, mastering its use can elevate the quality of your work and help you tackle projects more efficiently. But what exactly is a speed square, and how can it revolutionize your workflow? This guide covers everything you need to know.

In this comprehensive guide, we’ll explore the history, uses, and techniques associated with the speed square. We’ll also dive into its design, key features, and even offer some tips for choosing the right one for your needs. So, let’s get started and unlock the full potential of this underrated tool!

- Cash Cobain Upcoming Events Everything You Need To Know

- Ultimate Guide To Styling And Caring For Pink Pom Puff Jackets

Table of Contents

- What is a Speed Square?

- The History of the Speed Square

- Features and Design of a Speed Square

- Why is a Speed Square Essential for Carpenters?

- How to Use a Speed Square Effectively?

- What Angles Can You Mark with a Speed Square?

- Using a Speed Square as a Saw Guide

- How to Read the Markings on a Speed Square?

- Choosing the Right Speed Square for Your Toolbox

- Tips for Maintaining Your Speed Square

- Can a Speed Square Be Used for Metalworking?

- Common Mistakes to Avoid When Using a Speed Square

- Frequently Asked Questions

- Conclusion

What is a Speed Square?

The speed square, also known as a rafter square or triangle square, is a triangular-shaped hand tool used in woodworking and carpentry. Its primary purpose is to mark angles and make accurate cuts, but its versatility has earned it a place in a wide range of applications. Typically made of aluminum, steel, or plastic, it’s lightweight yet durable enough to withstand the rigors of job sites.

Speed squares have a right angle (90 degrees) and a 45-degree angle built into their design, making them ideal for tasks that require precision. They often feature markings for common measurements, allowing users to quickly and easily draw straight lines or mark angles without additional tools.

In addition to its traditional uses, the speed square can serve as a protractor, saw guide, ruler, and even a guide for roofing measurements. Its compact size makes it easy to carry in your tool belt, ensuring you’re always prepared to tackle a variety of tasks.

- The Ultimate Guide To Beddys Bedding Comfort Style And Convenience

- The Story Behind The Viral Yao Ming Meme A Cultural Phenomenon Explained

The History of the Speed Square

The speed square was invented in 1925 by Albert Swanson, a carpenter who wanted to simplify the process of measuring angles and making precise cuts. He designed the tool as a combination of several existing tools, including a framing square, try square, and protractor. Swanson patented his invention and launched the Swanson Tool Company, which still manufactures speed squares to this day.

The tool quickly gained popularity among carpenters and DIY enthusiasts due to its functionality and ease of use. Over the years, the design has remained largely unchanged, a testament to its effectiveness. Modern versions of the speed square incorporate additional features, such as etched markings for improved visibility and durability.

Today, the speed square is a staple in toolboxes worldwide, valued for its simplicity, versatility, and reliability. Its enduring appeal lies in its ability to perform multiple tasks with precision, making it an essential tool for professionals and hobbyists alike.

Features and Design of a Speed Square

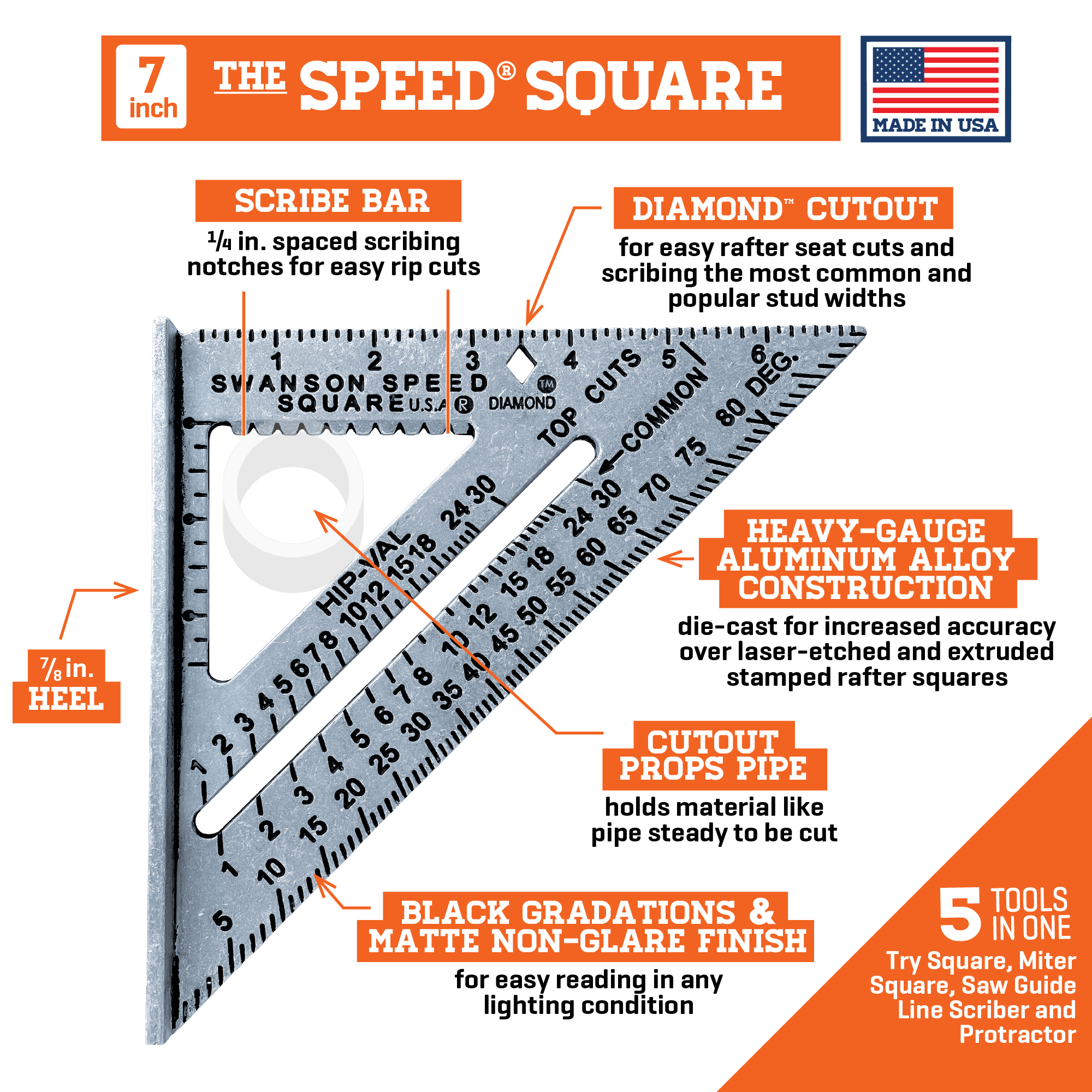

The design of a speed square is both simple and ingenious. Its triangular shape includes a pivot point, a base, and a hypotenuse, which collectively allow for a variety of functions. Let’s break down its key features:

- Pivot Point: This is the corner where the base and hypotenuse meet, serving as the starting point for marking angles.

- Base: The straight edge of the triangle, used for aligning the tool with the edge of the material being measured or cut.

- Hypotenuse: The longest side of the triangle, which often includes degree markings for measuring angles.

- Scribe Notches: Small cutouts along the base for marking parallel lines.

- Degree Markings: Graduations etched or printed along the hypotenuse for measuring angles accurately.

These features make the speed square an incredibly versatile tool, capable of performing a wide range of functions with minimal effort. Whether you’re framing, roofing, or simply making straight cuts, the speed square is designed to make your job easier.

Why is a Speed Square Essential for Carpenters?

For carpenters, precision is key. A slight miscalculation in measurement or angle can lead to wasted materials and compromised structural integrity. This is where the speed square comes into play. Its ability to provide accurate measurements and markings ensures that every cut and joint fits perfectly.

Here are some reasons why the speed square is indispensable for carpenters:

- Accuracy: The tool’s built-in angles and markings eliminate guesswork, ensuring precise measurements every time.

- Versatility: From marking angles to serving as a saw guide, the speed square can handle multiple tasks.

- Efficiency: Its compact design and ease of use save time, allowing carpenters to focus on their craft.

- Durability: Made from robust materials, the speed square can withstand the demands of job sites.

Whether you’re building a deck, installing trim, or constructing a roof, the speed square is a tool you can rely on to get the job done right.

How to Use a Speed Square Effectively?

Using a speed square may seem straightforward, but mastering its various functions can significantly enhance your efficiency and accuracy. Here’s a step-by-step guide on how to use this versatile tool:

Step 1: Marking a Straight Line

To draw a straight line, place the base of the speed square flush against the edge of the material. Use a pencil to trace along the hypotenuse, creating a perfect straight line.

Step 2: Measuring Angles

Align the pivot point with the corner of the material and rotate the square to the desired angle. Use the degree markings along the hypotenuse to ensure accuracy, then mark the angle with a pencil.

Step 3: Using as a Saw Guide

Position the base of the speed square against the edge of the material and hold it firmly in place. Align your saw blade with the hypotenuse to make precise cuts at 90 or 45 degrees.

By practicing these techniques, you’ll quickly become proficient in using a speed square for a variety of tasks, making it an invaluable addition to your toolkit.

What Angles Can You Mark with a Speed Square?

The speed square is designed to mark two primary angles: 90 degrees and 45 degrees. However, its versatility doesn’t end there. Thanks to its degree markings, it can also be used to measure and mark any angle between 0 and 90 degrees.

For tasks that require precise angle measurements, such as cutting rafters or stair stringers, the speed square’s ability to mark custom angles is invaluable. Simply align the pivot point with the material’s edge and rotate the square until the desired angle aligns with the edge. This feature makes it an essential tool for both basic and complex carpentry projects.

Using a Speed Square as a Saw Guide

One of the most practical applications of a speed square is its use as a saw guide. This function is particularly useful for making straight cuts with a circular saw. Here’s how to do it:

- Place the base of the speed square flush against the material’s edge.

- Position the saw blade along the hypotenuse of the square.

- Hold the square firmly in place to prevent slipping.

- Activate the saw and guide it along the square for a clean, straight cut.

Using a speed square as a saw guide not only improves accuracy but also ensures consistent results, making it a go-to tool for carpenters and DIY enthusiasts alike.

How to Read the Markings on a Speed Square?

The markings on a speed square can seem overwhelming at first, but understanding them is key to unlocking its full potential. These markings typically include:

- Degree Markings: Located along the hypotenuse, these indicate angles from 0 to 90 degrees.

- Common and Hip/Valley Rafter Scales: These are used for cutting rafters and calculating roof pitches.

- Inch Markings: Found along the base, these function as a ruler for measuring lengths.

By familiarizing yourself with these markings and practicing their use, you can quickly and accurately perform a wide range of tasks with your speed square.

Choosing the Right Speed Square for Your Toolbox

Not all speed squares are created equal, and choosing the right one can make a significant difference in your projects. Consider the following factors:

- Material: Aluminum and steel squares are more durable, while plastic models are lightweight and affordable.

- Size: Standard sizes range from 6 to 12 inches, with larger squares offering more versatility.

- Markings: Ensure the markings are easy to read and etched for durability.

By selecting a speed square that meets your needs and preferences, you’ll be better equipped to tackle a variety of tasks with confidence.

Tips for Maintaining Your Speed Square

Proper care and maintenance can extend the lifespan of your speed square and ensure its accuracy. Here are some tips:

- Clean the square regularly to remove dirt and debris.

- Store it in a dry place to prevent rust or corrosion.

- Inspect the markings periodically to ensure they remain legible.

By following these simple steps, you can keep your speed square in excellent condition for years to come.

Can a Speed Square Be Used for Metalworking?

While the speed square is primarily designed for woodworking, it can also be used for certain metalworking tasks. Its durable construction and precise markings make it suitable for measuring and marking metal surfaces. However, it’s important to note that prolonged use on hard materials may cause wear and tear, so exercise caution and choose a square made of robust materials if you plan to use it for metalworking.

Common Mistakes to Avoid When Using a Speed Square

Even the most experienced users can make mistakes when using a speed square. Here are some common pitfalls to watch out for:

- Incorrect Alignment: Ensure the base is flush against the material’s edge for accurate measurements.

- Using a Damaged Square: Inspect your tool for damage or wear, as this can compromise its accuracy.

- Neglecting Maintenance: Regular cleaning and care are essential to preserve the tool’s functionality.

By avoiding these mistakes, you can maximize the effectiveness of your speed square and achieve better results in your projects.

Frequently Asked Questions

1. What is the primary use of a speed square?

The primary use of a speed square is to mark angles and make precise cuts in woodworking and carpentry projects.

2. Can I use a speed square with a circular saw?

Yes, a speed square can be used as a saw guide to make straight cuts with a circular saw.

3. What materials are speed squares made of?

Speed squares are typically made of aluminum, steel, or plastic, each offering different levels of durability and affordability.

4. Are speed squares only for professionals?

No, speed squares are suitable for both professionals and DIY enthusiasts due to their simplicity and versatility.

5. How do I maintain my speed square?

Regular cleaning, proper storage, and periodic inspections can help maintain the accuracy and longevity of your speed square.

6. Can a speed square measure angles other than 90 and 45 degrees?

Yes, the degree markings on the hypotenuse allow you to measure and mark any angle between 0 and 90 degrees.

Conclusion

The speed square is a versatile and indispensable tool that simplifies a wide range of tasks in woodworking and carpentry. From marking angles to serving as a saw guide, its functionality and ease of use make it a must-have for professionals and DIY enthusiasts alike. By understanding its features, mastering its techniques, and maintaining it properly, you can unlock the full potential of this simple yet powerful tool. Whether you're building, repairing, or crafting, the speed square is your trusted companion for achieving precision and efficiency.

- Brother Uhhh Meme A Deep Dive Into The Viral Internet Trend

- All You Need To Know About Crazy Ga A Unique Phenomenon

Speed® Square Swanson Tool Company

Speed® Square Swanson Tool Company